Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

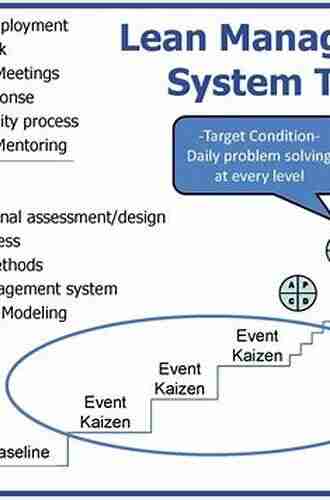

Lean Management System (LMS): Revolutionizing Efficiency and Effectiveness

In today's fast-paced business world, organizations are constantly striving to improve their operations, eliminate waste, and enhance productivity. One approach that has gained significant traction is Lean Management System (LMS),a methodology that focuses on reducing non-value-added activities and maximizing customer value. In this article, we will explore the key principles, benefits, and implementation strategies of Lean Management System.

Understanding Lean Management System

Lean Management System is heavily influenced by the Lean Manufacturing principles developed by Toyota in the 1950s. It is a systematic approach that aims to create a culture of continuous improvement by identifying and eliminating waste throughout the entire value stream. By optimizing processes and enhancing efficiency, organizations can deliver higher quality products and services while minimizing costs and maximizing customer satisfaction.

Key Principles of Lean Management System

There are five core principles that form the foundation of Lean Management System:

4.2 out of 5

| Language | : | French |

| File size | : | 7937 KB |

| Text-to-Speech | : | Enabled |

| Enhanced typesetting | : | Enabled |

| Print length | : | 64 pages |

- Identify Value: Lean organizations focus on understanding what customers truly value and align their operations accordingly. This helps in prioritizing activities that directly contribute to customer satisfaction and eliminating those that do not.

- Map the Value Stream: This involves following the flow of products or services from start to finish, identifying all the steps, and analyzing each process for waste or bottlenecks. By visualizing the entire value stream, organizations can identify areas for improvement.

- Create Flow: Once waste has been identified and removed, the next step is to create a smooth and uninterrupted flow of work. This requires streamlining processes, eliminating unnecessary delays, and synchronizing activities to deliver value to customers in the most efficient way possible.

- Establish Pull: Lean organizations strive to avoid overproduction and instead focus on producing only what the customer demands. By establishing a pull system, where work is initiated based on customer demand, organizations can prevent excess inventory and reduce waste.

- Pursue Perfection: Continuous improvement is at the heart of Lean Management System. Organizations must constantly strive to optimize processes, eliminate waste, and enhance productivity. This involves fostering a culture of learning, empowering employees, and encouraging innovation.

Benefits of Implementing Lean Management System

Implementing Lean Management System can lead to numerous benefits for organizations, including:

- Improved operational efficiency

- Reduced lead times

- Enhanced product quality

- Increased customer satisfaction

- Reduced costs and waste

- Empowered and engaged employees

- Greater competitive advantage

Implementing Lean Management System

While implementing Lean Management System requires commitment and dedication, following a structured approach can greatly increase the chances of success. Here are some key steps to consider:

- Gain Leadership Support: Executives and leaders must be fully committed to the Lean journey and provide the necessary resources and support for its implementation.

- Engage and Empower Employees: Lean Management System is a team effort that requires involvement and engagement from employees at all levels. Encourage their active participation and empower them to propose improvements.

- Identify and Prioritize Opportunities: Conduct a thorough analysis of the current state of operations and identify areas with the highest potential for improvement. Prioritize these opportunities based on their impact and feasibility.

- Implement Standardized Work: Establish clear, standardized procedures and work instructions to ensure consistency and promote efficiency.

- Continuously Measure and Improve: Implement key performance indicators (KPIs) and regularly track progress. Use data to identify areas for further improvement and take appropriate actions.

- Develop a Learning Culture: Foster a culture of continuous learning and improvement. Encourage knowledge sharing, provide training opportunities, and recognize and reward innovative ideas.

Lean Management System (LMS) offers a powerful approach for organizations to streamline their operations, eliminate waste, and enhance productivity. By embracing the principles of Lean, organizations can deliver higher value to customers while minimizing costs and maximizing efficiency. Remember, implementing Lean Management System is a journey, and continuous improvement must be ingrained into the organization's culture. Start today and revolutionize your organization's efficiency and effectiveness!

4.2 out of 5

| Language | : | French |

| File size | : | 7937 KB |

| Text-to-Speech | : | Enabled |

| Enhanced typesetting | : | Enabled |

| Print length | : | 64 pages |

The success of a Lean manufacturing program depends far more on organization-wide leverage of Lean manufacturing tools than it does on the tools themselves. To this the organization must add the human relations aspects that earn buy-in and engagement by all members of the workforce, to the extent that workers will react immediately and decisively t

Drew Bell

Drew BellCompulsion Heidi Ayarbe - A Gripping Tale of Addiction...

Compulsion Heidi Ayarbe...

Guy Powell

Guy PowellThe Cottonmouth Club Novel - Uncovering the Secrets of a...

Welcome to the dark and twisted world of...

Ira Cox

Ira CoxThe Sociopolitical Context Of Multicultural Education...

Living in a diverse and interconnected world,...

Jesse Bell

Jesse BellThe Epic Journey of a Woman: 3800 Solo Miles Back and...

Embarking on a solo journey is a...

Cody Blair

Cody BlairFlorida Irrigation Sprinkler Contractor: Revolutionizing...

Florida, known for its beautiful...

Walt Whitman

Walt WhitmanUnveiling the Political Tapestry: Life in Israel

Israel, a vibrant country located in the...

Allan James

Allan JamesLife History And The Historical Moment Diverse...

Do you ever find yourself...

George Bernard Shaw

George Bernard ShawMiami South Beach The Delaplaine 2022 Long Weekend Guide

Welcome to the ultimate guide for...

Edison Mitchell

Edison MitchellAn In-depth Look into the Principles of the Law of Real...

The principles of the...

Caleb Carter

Caleb CarterExclusive Data Analysis Explanations For The October 2015...

Are you preparing for the Law School...

Alexandre Dumas

Alexandre DumasThe Secret to Enjoying Motherhood: No Mum Celebration of...

Being a mother is a truly remarkable...

Wesley Reed

Wesley ReedRace Walking Record 913 October 2021

Are you ready for an...

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Charles DickensHow To Write Killer Copy Fast - Be a Pro Wordsmith with These Effective Tips!

Charles DickensHow To Write Killer Copy Fast - Be a Pro Wordsmith with These Effective Tips!

Chinua AchebeThe Annotated Crome Yellow by Aldous Huxley - Unveiling a Thought-Provoking...

Chinua AchebeThe Annotated Crome Yellow by Aldous Huxley - Unveiling a Thought-Provoking...

Orson Scott CardGuide To Playing The Ocean Course On Kauai Golf Kauai: Uncover Paradise on...

Orson Scott CardGuide To Playing The Ocean Course On Kauai Golf Kauai: Uncover Paradise on... Eliot FosterFollow ·4.2k

Eliot FosterFollow ·4.2k Salman RushdieFollow ·5k

Salman RushdieFollow ·5k Dean CoxFollow ·19.4k

Dean CoxFollow ·19.4k Adam HayesFollow ·15.4k

Adam HayesFollow ·15.4k Jaime MitchellFollow ·3.9k

Jaime MitchellFollow ·3.9k Israel BellFollow ·4.4k

Israel BellFollow ·4.4k Bruce SnyderFollow ·18.8k

Bruce SnyderFollow ·18.8k August HayesFollow ·4.3k

August HayesFollow ·4.3k